Your cart

There are no more items in your cart

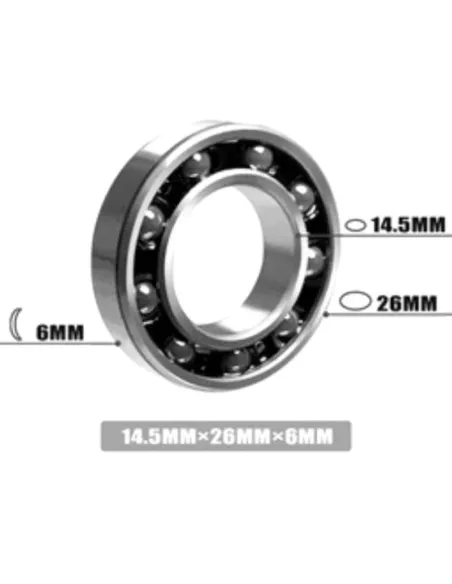

Rear Engine Bearing - Hybrid Ceramic 14.5x26x6mm Fussion FS-BE025-C

Notice Of Availability!

€18.17

This is a 14.5x26x6mm Hybryd Ceramic Rear Engine Bearing, and is intended for use with any nitro engine that requires a 14.5x26x6mm rear bearing. Fussion engine bearings offer decreased resistance, increased speed, load handling capabilities and extended bearing life. The bearing dimensions are 14.5mm inner, 26mm outer and 6mm thick. This bearing is open to allow oil to lubricate the bearings during use. This bearing will also fit any other .21 to .28 competition engine that uses the same bearing dimensions.

They also have 2 distinct advantages when compared to other bearings:

Precision Ball Races: A unique bearing race design is used that increases load capabilities, centering the balls in the middle of bearing race. This allows the bearing to continue to rotate smoothly when the crankshaft is subjected to harsh side and radial loads.

PA46 Nylon Cage: A stronger, thicker bearing cage material has been developed that allows the bearings to withstand high nitro content fuel and excessive temperatures. The reinforced PA46 nylon has been subjected to Heat Distortion Temperatures of 554° without failure.

Our Fussion Hybrid Ceramic Engine Bearings are hybrid type, with stainless steel tracks with Si3N4 silicone nitride ceramic balls mounted in an internal polyamide cage. Ceramic bearings have many advantages over standard steel bearings, such as weight reduction, higher RPM capabilities, greater resistance to corrosion and wear, as well as less friction and vibration.

Advantages of Hybrid Ceramic:

High speed: hybrid bearings can reach a speed due to friction.

Lightweight: the weight of ceramics is 60% lighter than steel

Long service life: the life of hybrid bearings is 3 to 5 times longer than that of steel in comparable working conditions.

Self-lubricating: even with little or no lubrication, ceramic bearings will continue to run longer than steel under the same stress level due to their self-lubricating properties.

Corrosion resistance: hybrid bearings have excellent corrosion resistance and will continue to function while they are corroded.

High rigidity: the elastic proportion of ceramics is 1.5 times greater than that of steel, this dramatically increases the stiffness of the balls.

Low friction: ceramic materials have a low frictional force. Even under the limit lubrication conditions, the surfaces are extremely smooth, so their friction force is low and the rotational friction moment is low.

Wear Resistant: the microhardness of ceramics is far superior to that of steel.

NOTE: This bearing should be installed so that the balls face the rear of the engine (towards the backplate), in order to allow proper lubrication.

They also have 2 distinct advantages when compared to other bearings:

Precision Ball Races: A unique bearing race design is used that increases load capabilities, centering the balls in the middle of bearing race. This allows the bearing to continue to rotate smoothly when the crankshaft is subjected to harsh side and radial loads.

PA46 Nylon Cage: A stronger, thicker bearing cage material has been developed that allows the bearings to withstand high nitro content fuel and excessive temperatures. The reinforced PA46 nylon has been subjected to Heat Distortion Temperatures of 554° without failure.

Our Fussion Hybrid Ceramic Engine Bearings are hybrid type, with stainless steel tracks with Si3N4 silicone nitride ceramic balls mounted in an internal polyamide cage. Ceramic bearings have many advantages over standard steel bearings, such as weight reduction, higher RPM capabilities, greater resistance to corrosion and wear, as well as less friction and vibration.

Advantages of Hybrid Ceramic:

High speed: hybrid bearings can reach a speed due to friction.

Lightweight: the weight of ceramics is 60% lighter than steel

Long service life: the life of hybrid bearings is 3 to 5 times longer than that of steel in comparable working conditions.

Self-lubricating: even with little or no lubrication, ceramic bearings will continue to run longer than steel under the same stress level due to their self-lubricating properties.

Corrosion resistance: hybrid bearings have excellent corrosion resistance and will continue to function while they are corroded.

High rigidity: the elastic proportion of ceramics is 1.5 times greater than that of steel, this dramatically increases the stiffness of the balls.

Low friction: ceramic materials have a low frictional force. Even under the limit lubrication conditions, the surfaces are extremely smooth, so their friction force is low and the rotational friction moment is low.

Wear Resistant: the microhardness of ceramics is far superior to that of steel.

NOTE: This bearing should be installed so that the balls face the rear of the engine (towards the backplate), in order to allow proper lubrication.

No reviews

Customers who bought this product also bought:

Kyosho Inferno MP9 TKI2 / TKI3 - Spare Parts & Option Parts

Differential Bevel Gear Set Kyosho Inferno MP9 / MP10 / MP10T / GT3 IF402

Kyosho Inferno 7.5 / Neo / Neo Race Spec - Spare Parts & Option Parts

Grade Comments (0)